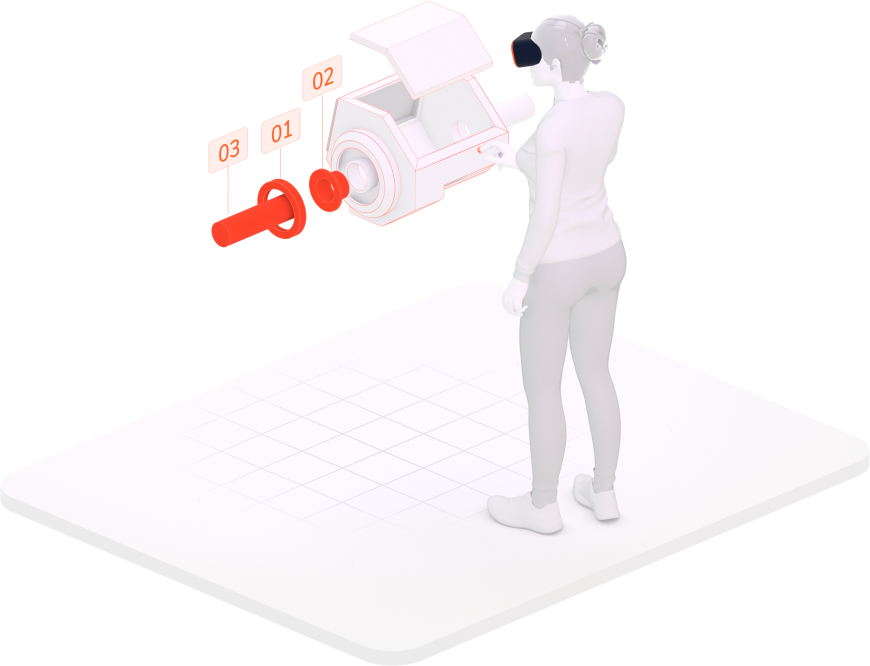

Product assembly in VR — tangible insights based on digital data

Start living the Design for Manufacturing philosophy. Use the advantages of the virtual world: Through the clear analysis of geometry and product structure you will quickly gain an understanding of individual assemblies and their contexts. Plan the installation and removal of parts. Test assembly sequences with realistic collisions. With Halocline Assembly you have the products in your virtual hands even before the first hardware prototypes are produced.

Understanding

You do not need any special knowledge to check your product design with Halocline Assembly. You can easily import existing CAD data. It is irrelevant whether the data is available as a native CAD file or in a standardized exchange format (overview of the supported formats). The visualization is done true to scale so that you can experience your product 1:1. Based on the CAD hierarchy of the model subassemblies can be taken apart and inspected. This makes even the smallest details visible and the connections between individual parts easier to understand.

At a glance:

- Import of CAD data for viewing in VR

- Visual inspection and analysis of 3D data

- Disassembly of assemblies

Trying it out

In a further step you can check the ease of part installation of your product. For this purpose, there are various analysis tools with which you can measure distances and generate sectional views, for example. Examine installation spaces and check for bottlenecks to ensure the accessibility of each individual parts. For a clear overview you can hide and show individual parts and assemblies at any time. To check assembly sequences, you can run through your installation scenarios and test for collisions in real time.

At a glance

- Distance measurement and generation of sectional views

- Investigation of building spaces and bottlenecks

- Real-time collision tests (BETA)

Further use

Halocline Assembly also offers you the possibility of defining subassemblies relevant for the assembling process independently of the functional CAD hierarchy. Thus, different assembly states of a product can be mapped. Based on this individual structure, you can create the optimal workspace design for the assembly process in Halocline Layout. Use the opportunity to test assembly contexts with all participants in the virtual factory and generate the appropriate manufacturing bill of materials (MBOM). By carrying out this process step early on in the course of industrial engineering, you can detect design errors more quickly and can reliably estimate assembly feasibility.

At a glance:

- Defining subassemblies

- Export of individual definable assemblies from CAD models

- Integration of the data in Halocline Layout for workplace design