Check & optimize ergonomics

Ergonomische Arbeitsplätze gestalten

Reading time: 2,5 min

Integrating ergonomic principles into workplace design ensures that the working environment meets the physical needs of employees. This promotes general well-being and helps to reduce stress and fatigue. However, considering ergonomics in planning can often prove complex. In this article you will learn how you can easily carry out an ergonomic assessment and optimization yourself.

How does it work?

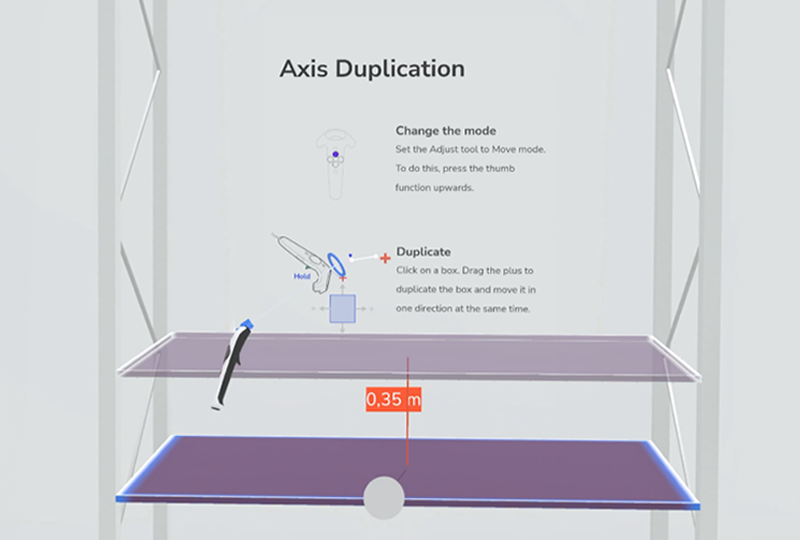

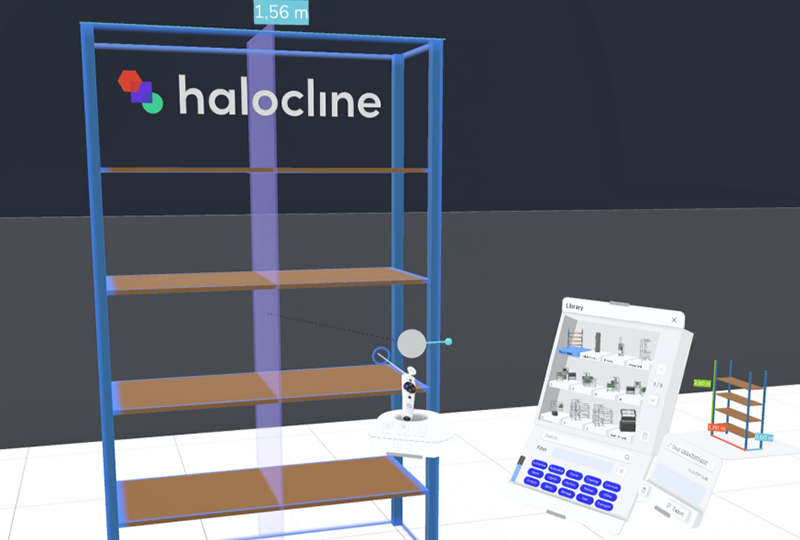

There are several ways to assess workstations from an ergonomic point of view. Already during the planning phase you can use the display of gripping spaces to optimally position frequently used equipment. Subsequently, the movements during the process can be recorded and automatically analyzed.

Checking gripping spaces & reach

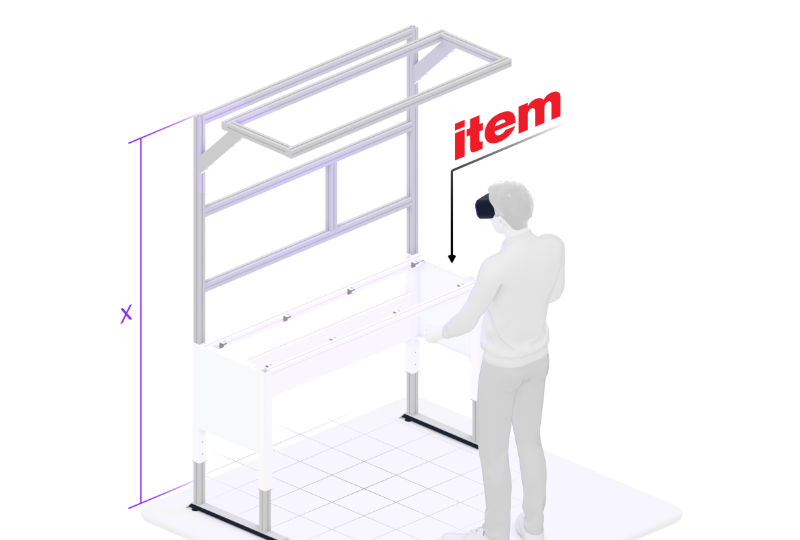

Use reach distances according to DIN standards or configure them according to your own standards. By placing an avatar at a workstation you have access to various visualizations that support you in planning. Use the display of the maximum and minimum reach of the employee to adapt the workstation. By creating different body sizes and shapes the workplace can be optimized individually for everyone.

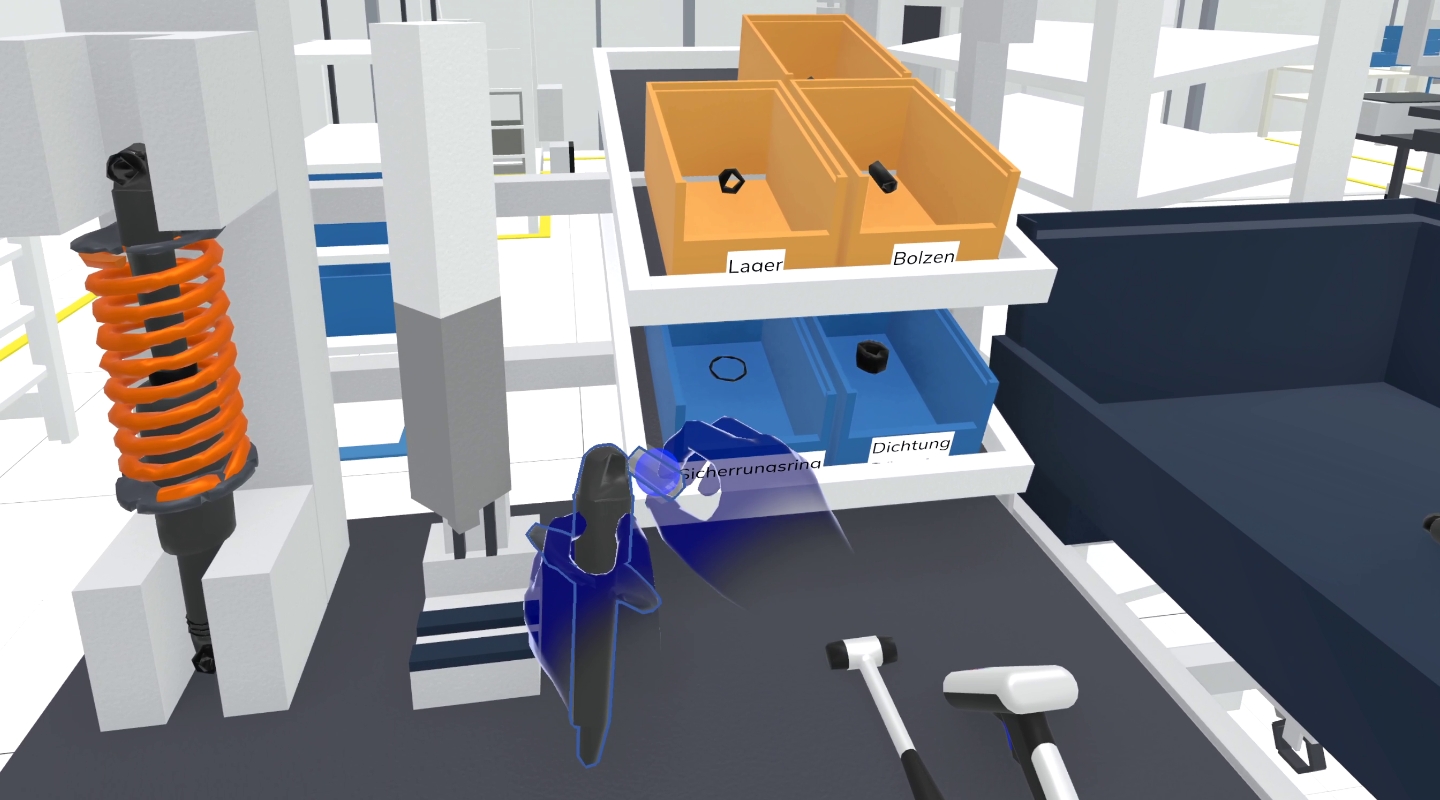

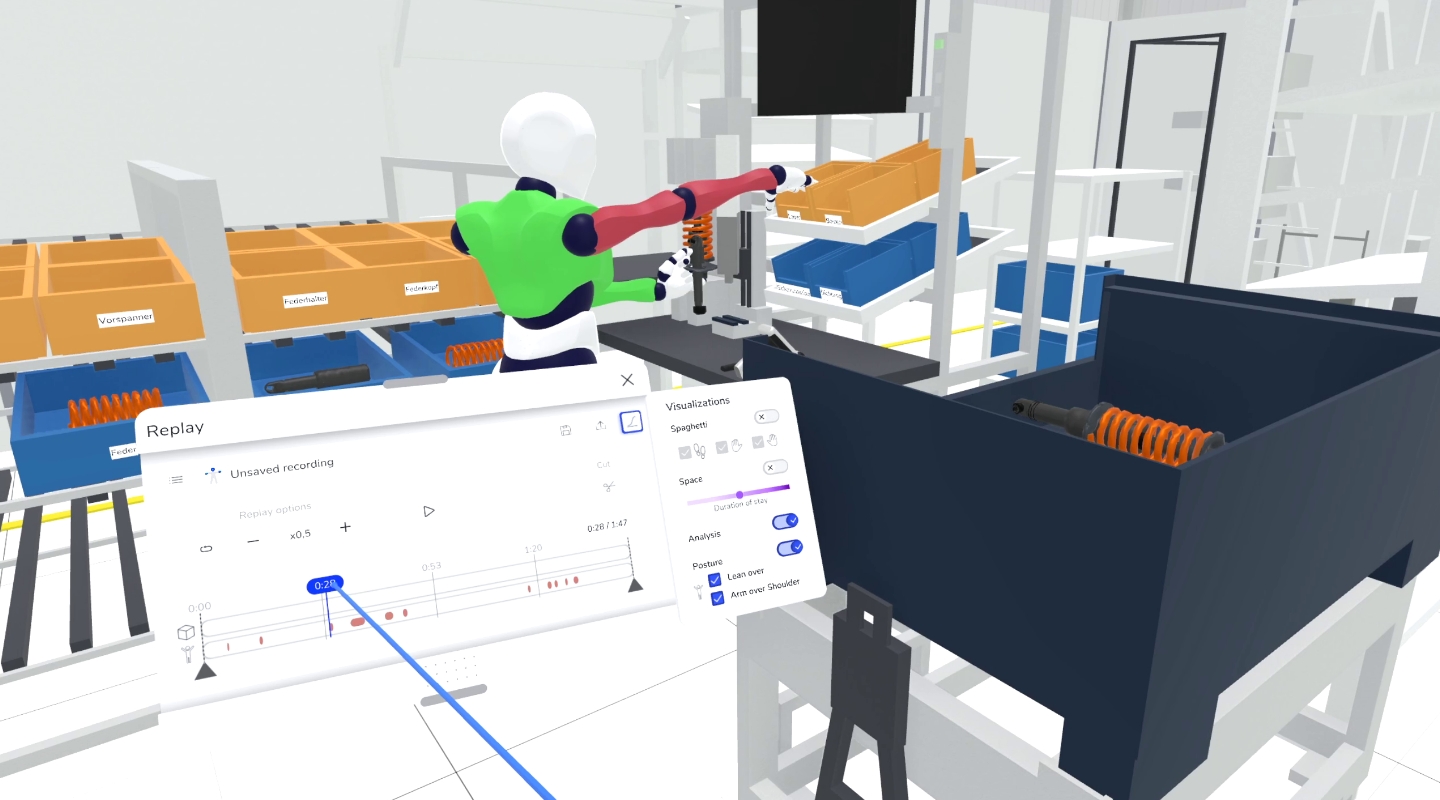

Record and analyze assembly processes

All movements in VR can be recorded — this is very convenient as you can perform your assembly as if in the real world and do not have to document every action manually. Afterwards you can replay the movements and see when and where ergonomically critical points are hidden.

Bending & stretching

Incorrect postures are recognized in the recording and highlighted. This makes it easy to see when objects are placed in such a way that employees have to bend down or stretch too far. These positions can be adjusted directly in VR and afterwards be checked again.

Taking weights into account

In Virtual Reality, of course, everything is as light as a feather — but in order to be able to include the stress caused by lifting weights, we offer an automatic analysis based on the key indicator method. This analyses how heavy, how long and how far objects are carried. Critical points are visually highlighted and can be examined in more detail. Solutions can also be worked out directly in VR.

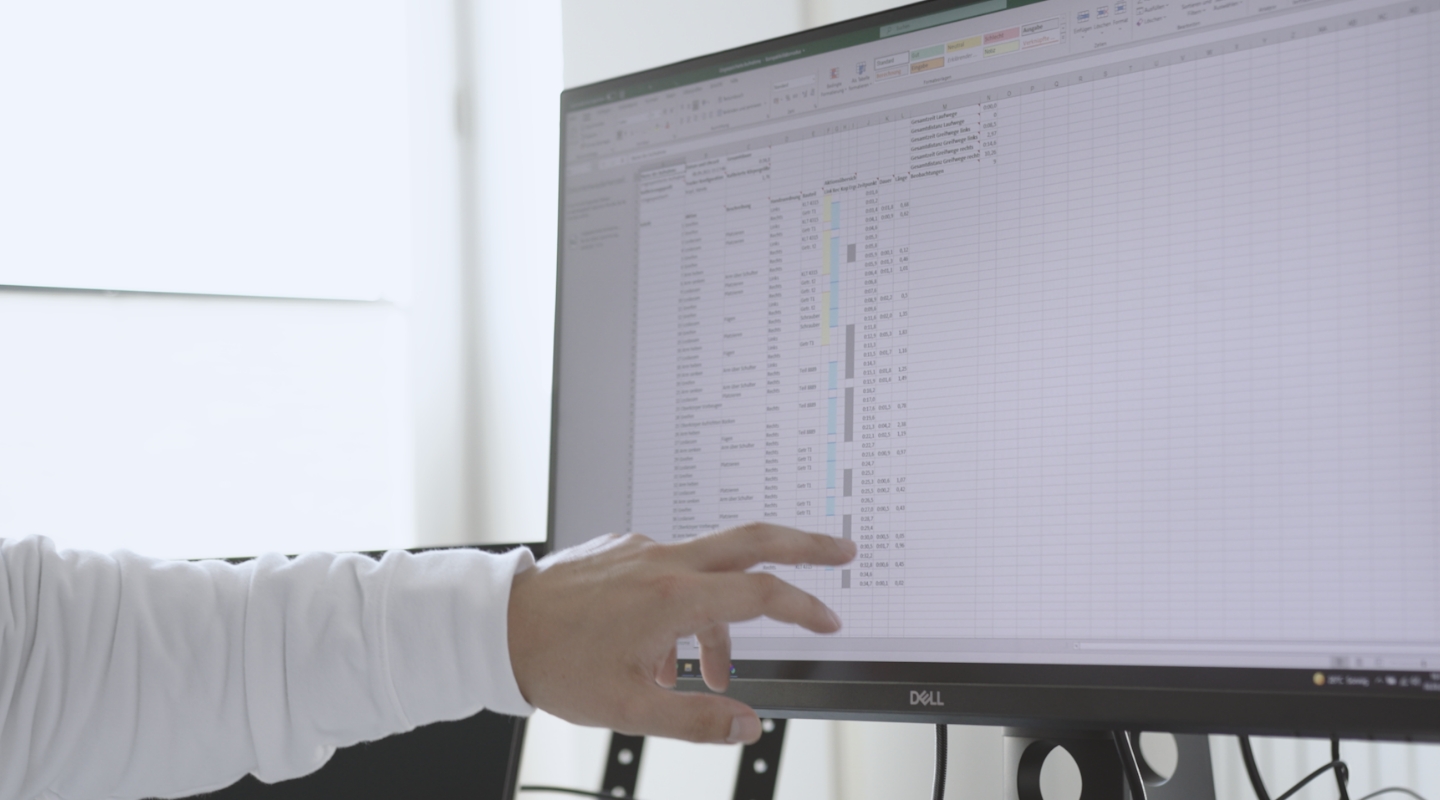

Export and reuse data

You can also use the collected data outside of Halocline. Video recordings and screenshots are very effective for a quick and clear communication of problem areas. This way you can convince even critical voices of the need for optimization.

In addition you receive all movements, grabbed objects and evaluations as a table. This allows you to compare processes and use them for further analyses.

Conclusion

Ergonomics analyses usually require a lot of time and expert knowledge, can be distorted by subjective assessments and, in the worst case, meet with resistance to necessary changes. Yet adherence to ergonomic guidelines is crucial for the well-being and productivity of our employees.

Halocline offers everyone the chance to make ergonomics an important topic as early as possible. Through easy-to-understand visualizations, ergonomic factors are given a voice during the early planning phase. With simple to create process recordings, ergonomics is included in the evaluation of a station and informed decisions can be made.

Together with Halocline, create workplaces that put the health of your employees first!