Including workers

Include expertise from the shopfloor into the planning process

Lesedauer: 1,5 min

Through their daily work on the shopfloor workers have completely internalized processes and can draw from an enormous amount of knowledge. However, in conventional planning processes with abstract words and models this is hardly taken into account. Virtual Reality (VR) makes it possible to bring people from the shopfloor into an environment where they can use their experience and provide valuable feedback.

Why workers should be more involved:

By trying out and helping to design the future workplaces in VR, workers are involved in the process and have the opportunity to give feedback at an early stage. This not only increases acceptance for changes, but also increases satisfaction and promotes solution-oriented thinking. In this way, you create more attractive workplaces for your skilled workforce.

How it works?

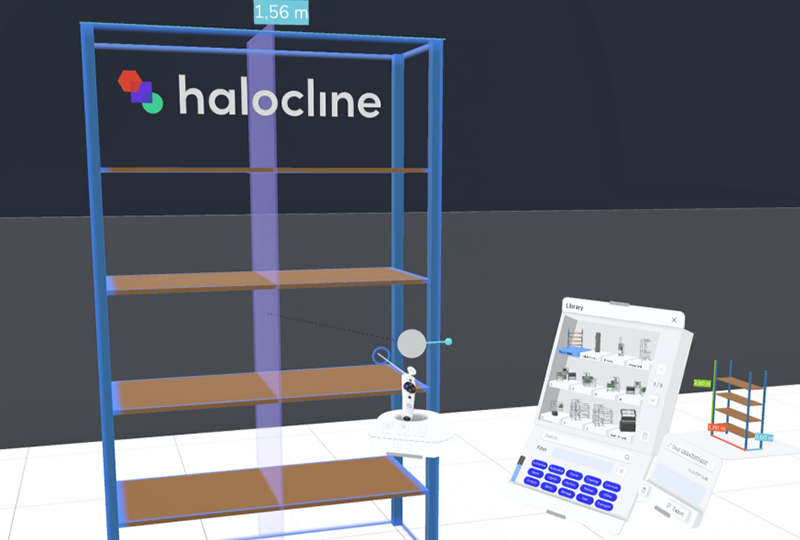

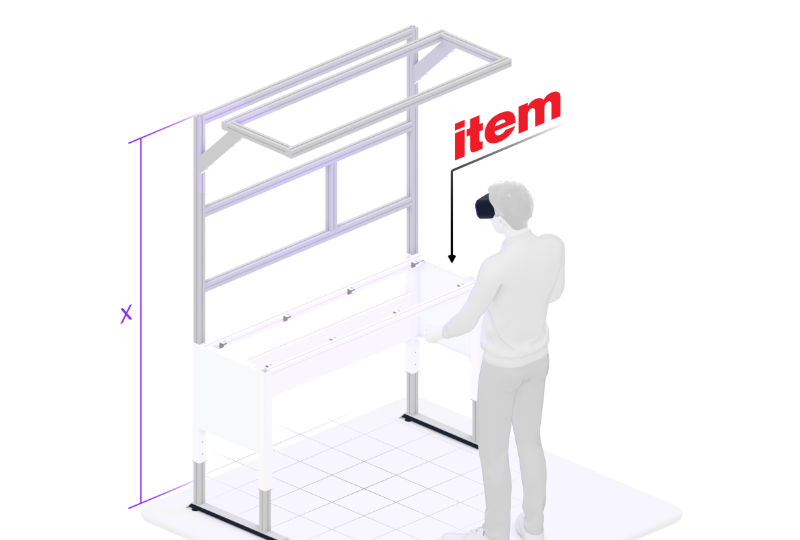

Halocline offers several ways to quickly involve other departments in the planning process, allowing everyone — even without software knowledge — to get involved. Some examples of how you can discuss your planning with others:

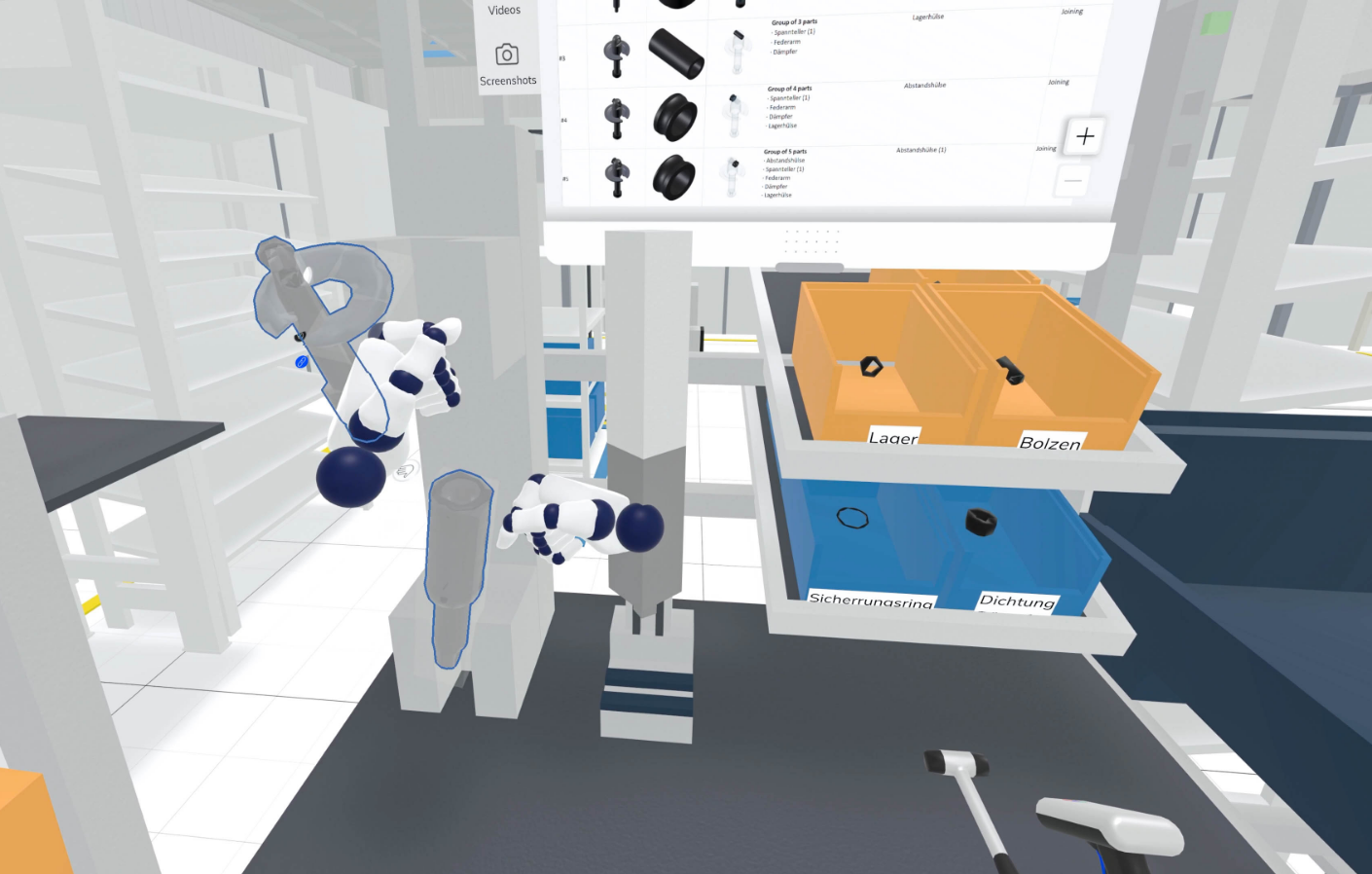

1. Assembly process testing

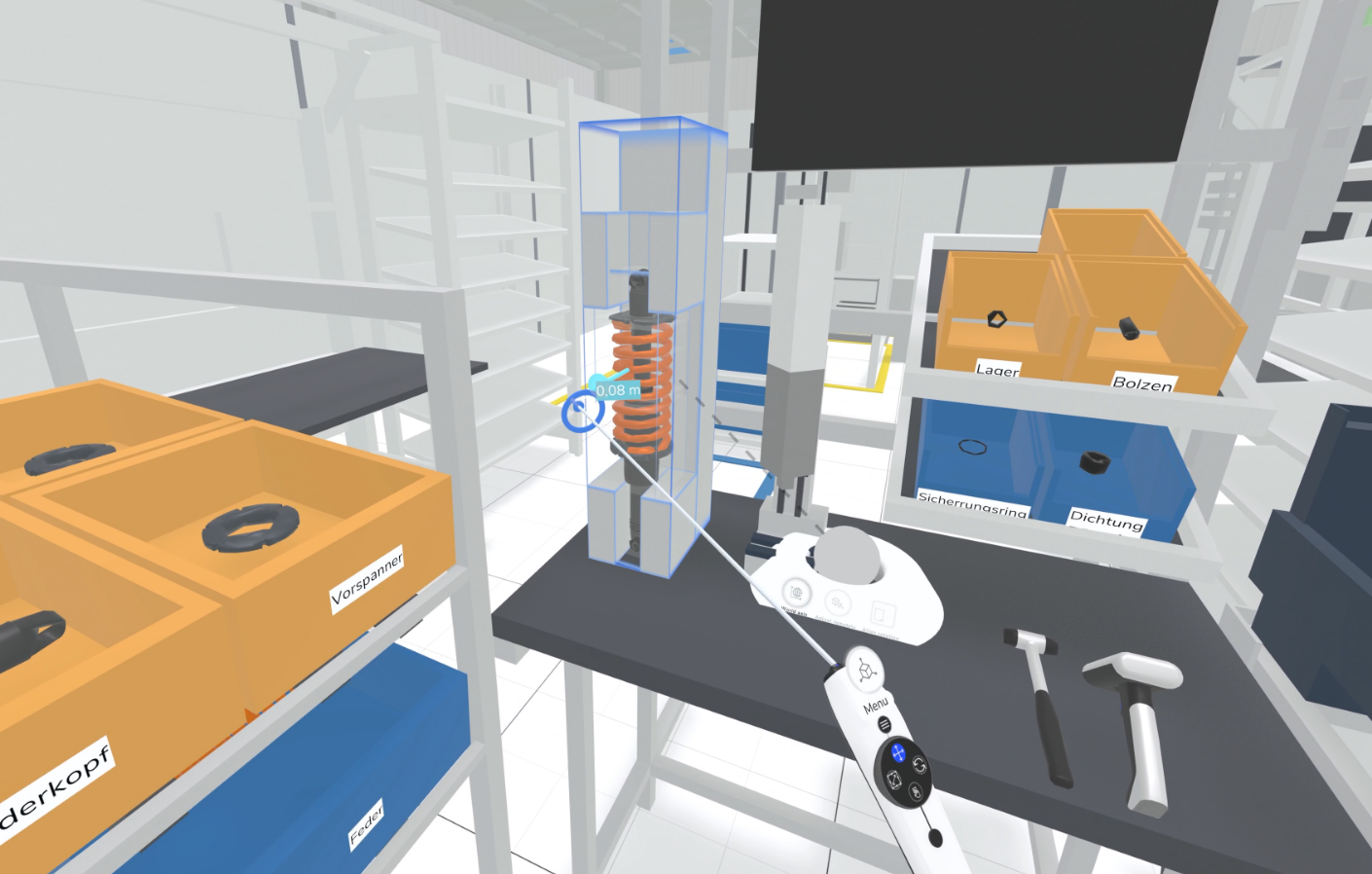

In Halocline Performance, interaction with the virtual world is just like in the real world. Workers can grip and assemble components with their hands. By doing so, they can easily test the process and give their assessment of ergonomics and process flow.

2. Analyze assembly process

Halocline offers the advantage that movements and processes are recorded. You can therefore play back the testing of the station again and again like a video. Through this individual steps and movements can be discussed together with the assembler.

As additional assistance you can show walking and gripping paths, movement spaces and ergonomics analyses. These are automatically derived from the motion recordings and make the various planning aspects clear and comprehensible.

3. Discuss & Document

Productive discussions arise when viewing the documentation together. Workers can record new ideas as spatial drawings with a pen — without any prior knowledge of software. In this way, solutions can be sketched and recorded with the help of simple markings.

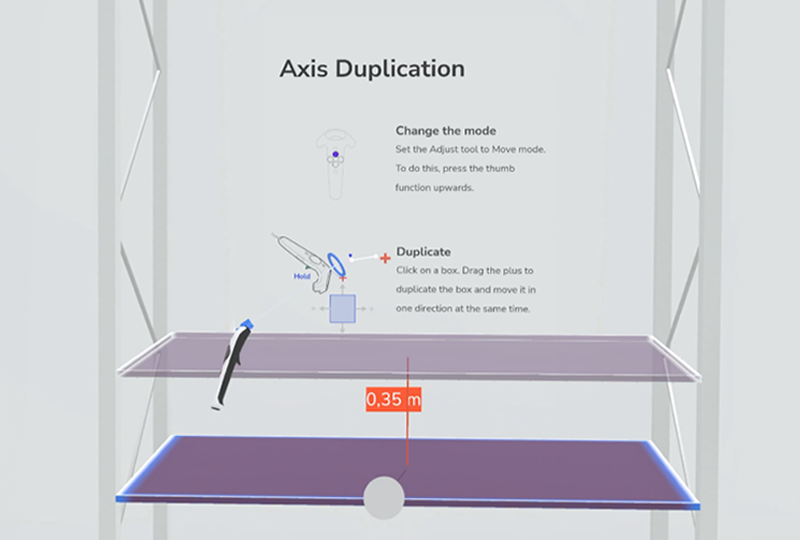

4. Directly implement changes

The seamless transition to Halocline Layout allows suggestions to be implemented directly. Simply try out ideas and find solutions within the same deadline. Then test them again, creating very fast and short iteration loops. This quickly produces solutions that work well for everyone involved.

Conclusion

Our customers report how they use Halocline to better involve their specialists in production planning. In particular, the possibility of virtual testing leads to new questions being raised and important details being addressed at an early stage. The workers are also extremely satisfied with this method, as they can now bring their ideas into the planning process at an early stage.

You too can incorporate the valuable know-how from the shopfloor into your planning. We will show you how it works!