Assembly manufacturability check

How an early check of the assemblability of products succeeds

“Once the BOM has been drawn up, we have nothing but problems to solve later on in production”. These and similar statements are regularly heard in exchanges with long-suffering industrial engineers in engineering. They complain about products and variants that cannot be built. The source of error: In order to complete an order quickly, processes are accelerated and essential intermediate steps are skipped.

Between the receipt of an order and the finished parts list, there are work steps that are urgently required in theory, but in practice are often put on the back burner in order to save time. In many cases, therefore, product design and development are already largely complete by the time the first prototypes reach the hands of workers. In order to avoid errors in buildability, this should ideally already be checked between the infeed and the determination of parts requirements. Buildability verification in assembly, however, relies on physical models.

The use of 3D printers has moved the point in time at which statements about buildability conditions can be made forward. Nevertheless, adjustments to individual components that only turn out to be unassemblable on the basis of the printed parts are already very time-consuming and expensive.

If inaccessibility of screw points or complicated mountability of assemblies then occurs during the first assembly, in many cases these can no longer be corrected. The product or variant is therefore not buildable and the result is complex and expensive production processes that often cannot meet the time and cycle specifications.

Checking products early in the process — with virtual reality

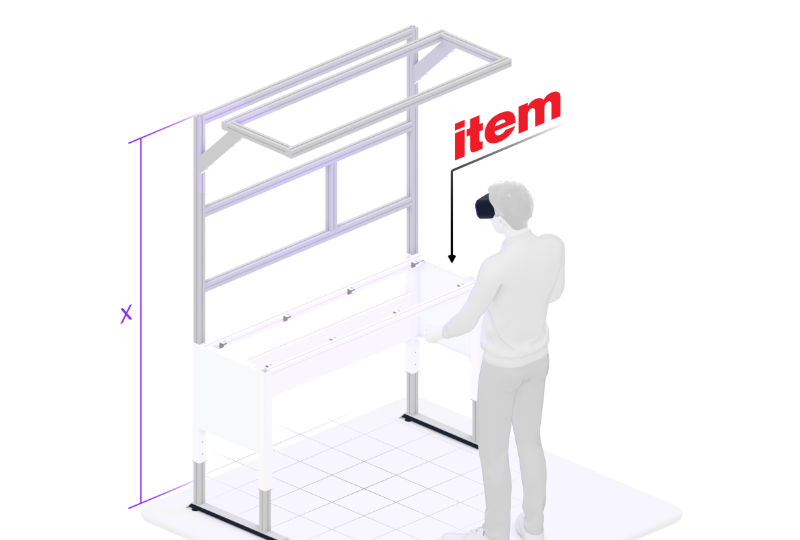

So the formula for happiness would actually be: Identify problems of buildability well before the first prototypes, so that products can already be verified in their structure and construction during the planning process. How can this be achieved on the basis of CAD data? By means of a virtual reality editor solution: By using Halocline Assembly, verifications of these essential success factors can already be carried out on the basis of 3D development data.

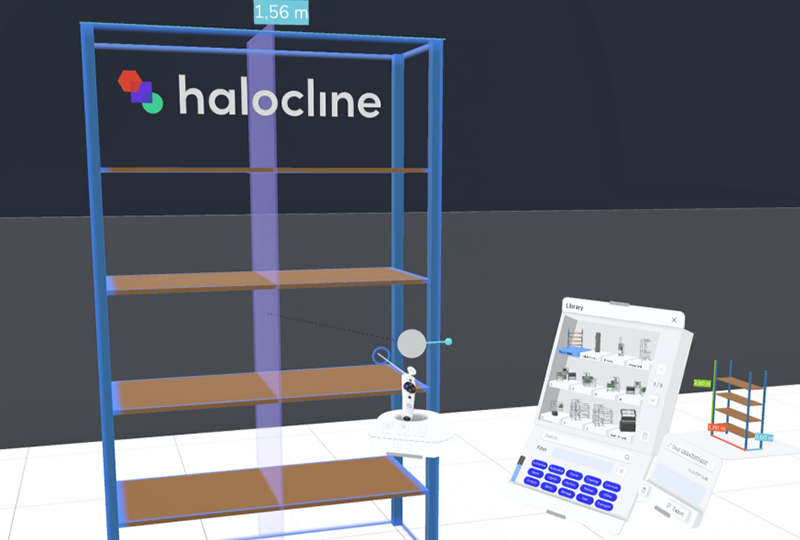

All common CAD data formats can be easily and quickly imported and experienced in VR in a very short time. Analogous to the structure of the model, assemblies can be disassembled, making even the smallest details visible and the relationship between individual components easier to understand. It is also possible to identify problems at this early stage of the product development process (PEP), which can usually only be detected very late with today’s tools.

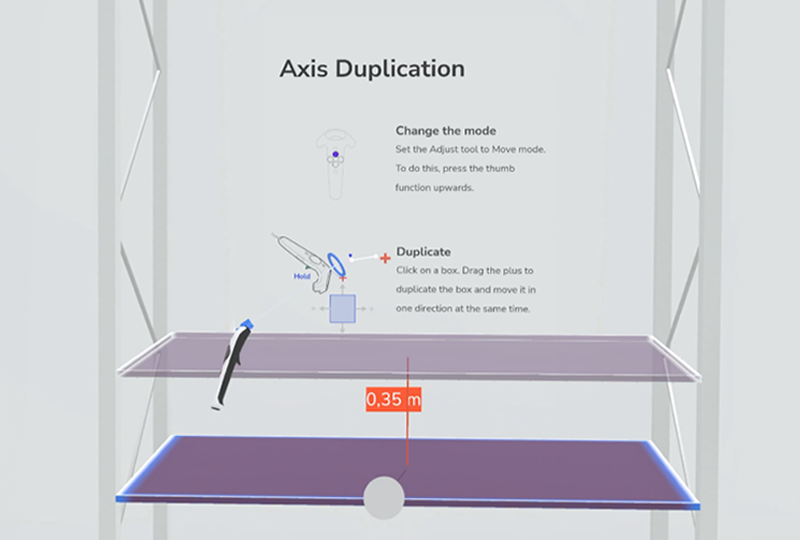

By means of a detailed physics simulation, components can be grasped and moved with the hands in the virtual factory. This form of intuitive work with digital data means that even people inexperienced with computers can work with CAD data and incorporate their many years of knowledge from production into the design and construction of new products. In this way, the knowledge of the top performers from production can also be used in the creation of the production bill of materials.

Difficult assembly situations and unfavorable positioning are noticed very early in the process and can be changed and optimized while a product is still in the development phase. Based on this buildability control, Design for Assembly gets a real chance!

With Halocline, no surprises arise at the start of production (SOP) due to the incorrect structure of the production bill of materials.