Planning item designs in Halocline

A cooperation for virtual industrial engineering

Who doesn’t know it: A few clicks and the online shopping is done. We want to save time in order to achieve a quick result. But can I – as a production planner – really guarantee that I implement an efficient and at the same time ergonomic manual workstation with my selection of fixtures from the online store?

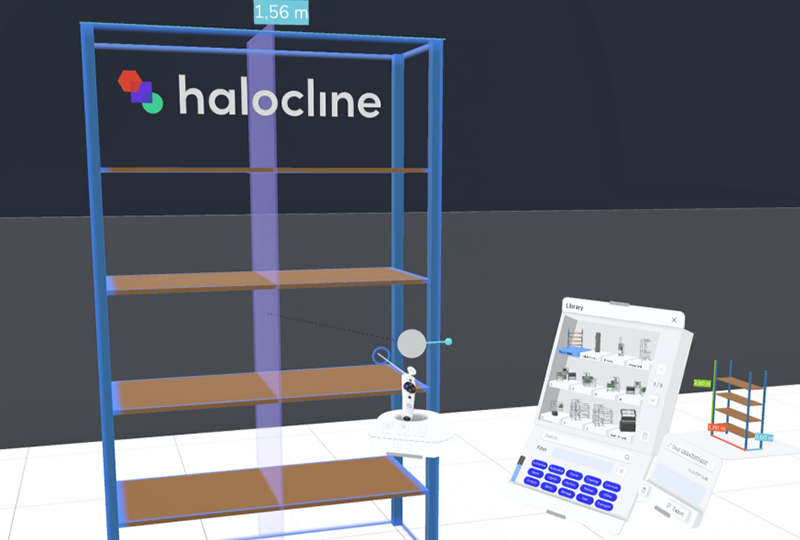

To ensure that the final result of the workplace design does not suffer, assembly workplaces should be equipped with precisely fitting solutions. And the best way to select these is to try them out and test them. Thanks to a cooperation between item and Halocline, this is now possible: with designs from the item engineering tool and Halocline’s VR environment, production environments can be planned spatially and experientially without the use of Cardboard Engineering or other prototypical setups.

This video shows you how you can also customize your item shelves.

Experience and individualize racks in VR

The item engineering tool allows free and rule-based 3D design. Project documentation and CAD data can be played out in various formats. If you want to customize an item shelf for your purposes, you can easily integrate it into your virtual hall layout in Halocline. For example, you can import a STEP file. Here you can try out the design in the context of the workspace, spatially and to scale. In this way, you can easily include and adapt item designs in your industrial engineering.

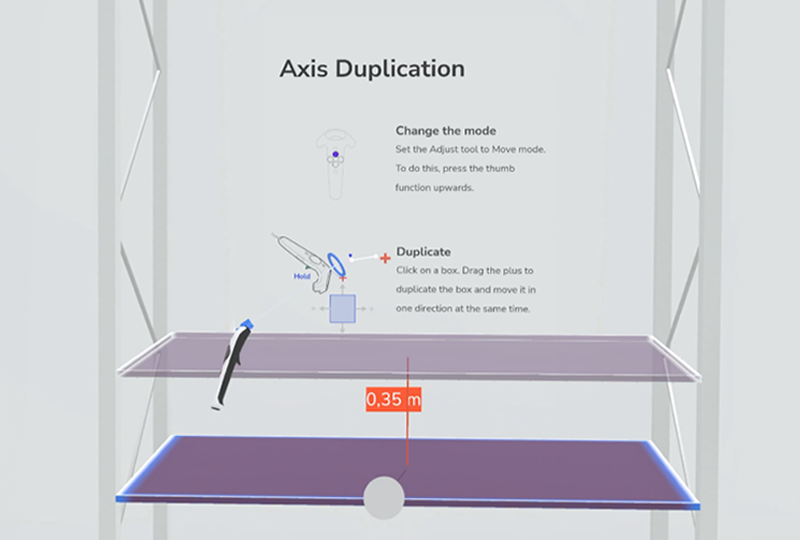

You individualize your rack by first placing it in the desired location of the resulting workstation. Not only can the position of the rack be individually adapted at any time, but the shelf surfaces can also be changed in height and width and roller conveyors can be adapted.

In addition to these adjustments, Halocline also allows you to experience and test the manual workstation. While you intuitively run through assembly processes in the virtual world, you can already take ergonomic requirements into account during the planning process. You can also estimate grasping spaces and walking distances, have them displayed, evaluate and plan them.

Once you have fitted a rack design into the workstation according to your requirements, you can simply switch to item’s engineering tool via the displayed link in Halocline to order your design.