Virtual Cardboard Engineering

Workstation design in VR — save time and cost with digital cardboard workshops

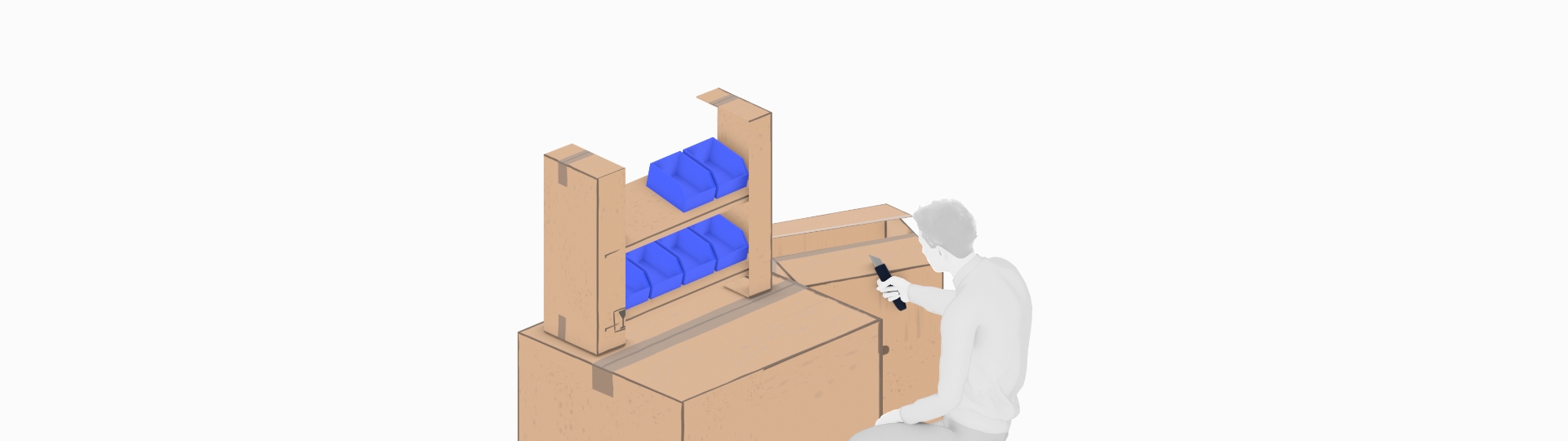

No matter if planning a new hall or continuous improvement on the shopfloor: the planning of workstations is essential for the efficiency of production and the health of the employees. Cardboard Engineering can make a meaningful contribution here, but is both space and time consuming and furthermore costly.

A lot of space is needed to realize classic cardboard structures: If insufficient space is available, external areas have to be rented or production areas have to be shut down for a longer time period. As a result, this fundamental step in industrial engineering is often skipped completely. A supposed cost saving, which can be often paid dearly in the aftermath.

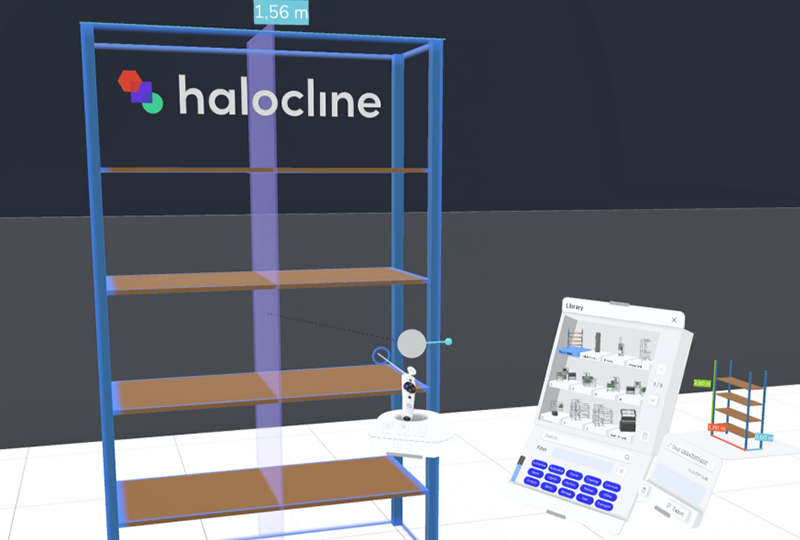

With Halocline Layout you can minimize space requirements and still plan three-dimensionally.

By using commercially available and low cost Virtual Reality hardware, entire factory halls can be planned on just 4 square meters of space at home or in the office.

Digital data instead of photo documentation

Even inexperienced users can create 3D models

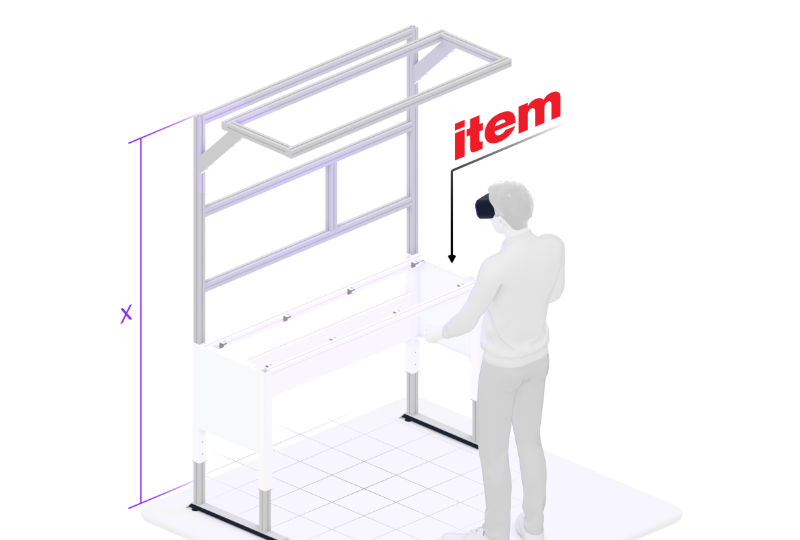

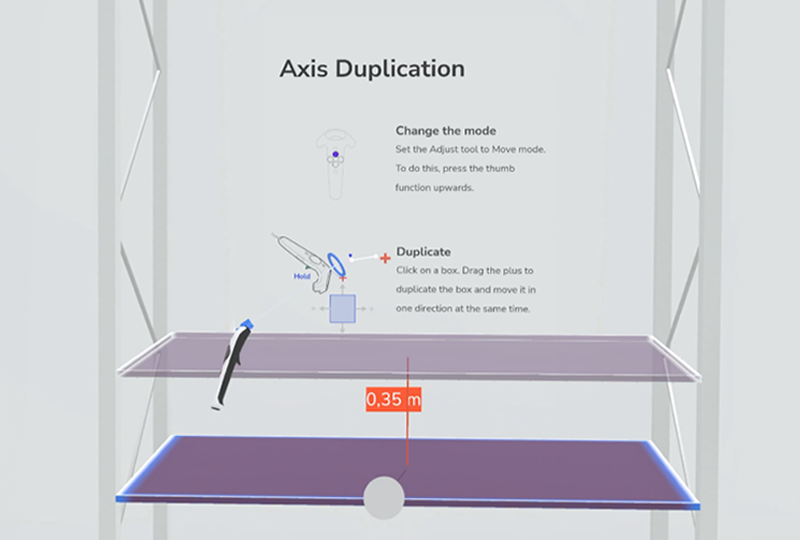

Halocline enables all disciplines involved to create 3D models in Virtual Reality themselves — according to their own ideas. By the intuitive and spatial planning in Halocline Layout and the testing of work processes in Halocline Performance, even people who are not computer-affine can be directly involved in the work and creation of digital data.

Previously, documentation in the form of photos was often the only outcome of an elaborate cardboard workshop. In this case, experts have to prepare this data in the form of drawings or CAD designs so that the knowledge gained and the resulting requirements can be passed on to suppliers.

With Halocline Layout, resources can be created directly in VR and passed on in digital form using various export functions. This minimizes the effort in the workshop as well as in further steps of industrial engineering.

4 times faster than conventional Cardboard Engineering

Less effort & more flexibility for Kautex Textron

“Compared to classic 3D planning, in virtual reality I am actually in the middle of a production line instead of just in front of it, and this gives me the opportunity to gain early insights into walking routes or even workplace design”.

Karl Koepke, Specialist Equipment

KAUTEX TEXTRON GmbH & Co. KG