Optimize processes

Reduce production processes and save costs

Reading time: 1,5 min

Keeping an eye on costs, time and quality is a challenge in production planning. Every move counts — but traditional planning requires a lot of imagination or complex setups to understand the effects of your planning. Halocline offers a solution in that processes can be tested, compared and optimized in Virtual Reality.

How does it work?

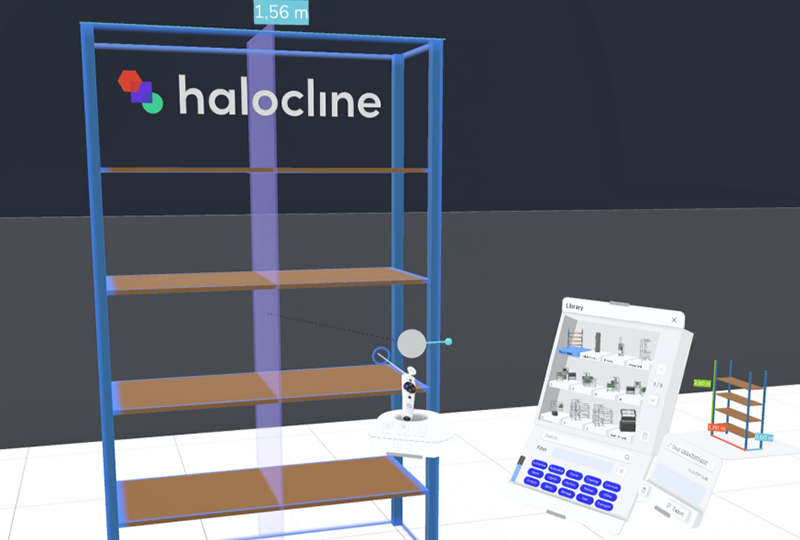

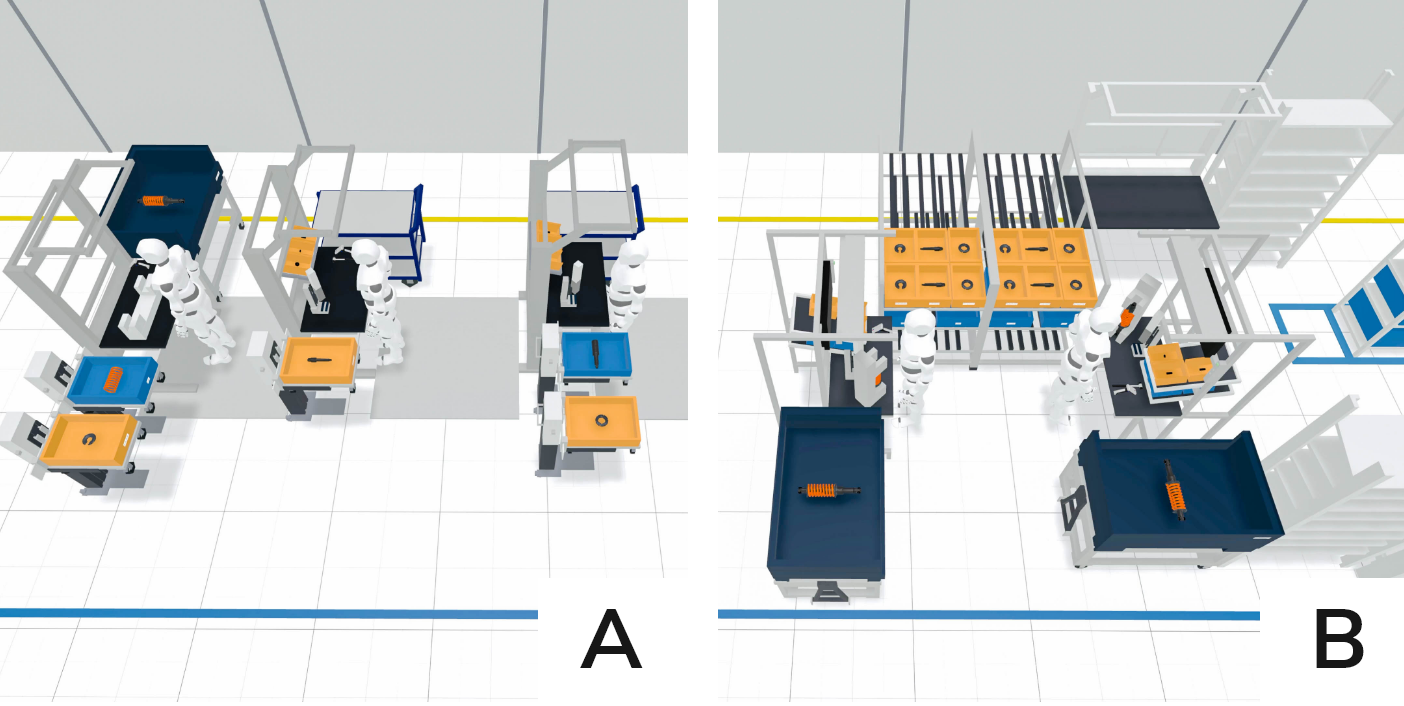

Create your layout

In Halocline Layout, you can create as many variants of your workstation as you like. After seamlessly switching to Halocline Performance, the assembly process can be tried out, recorded and analyzed.

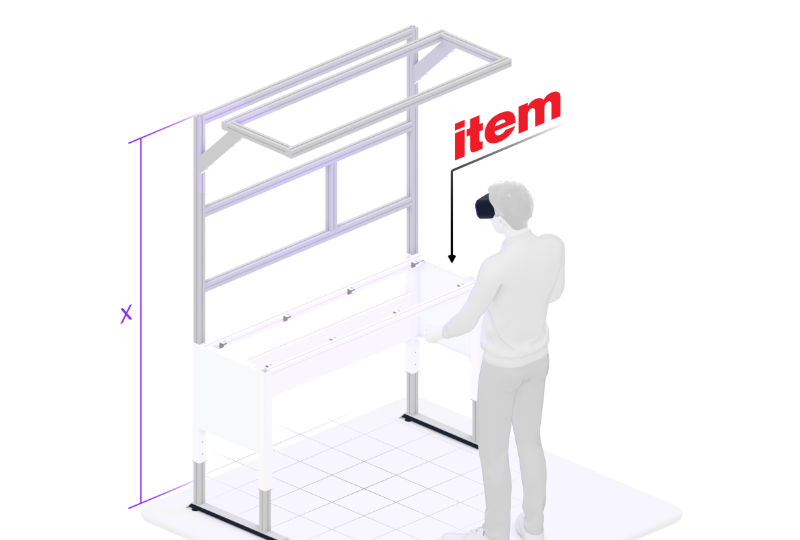

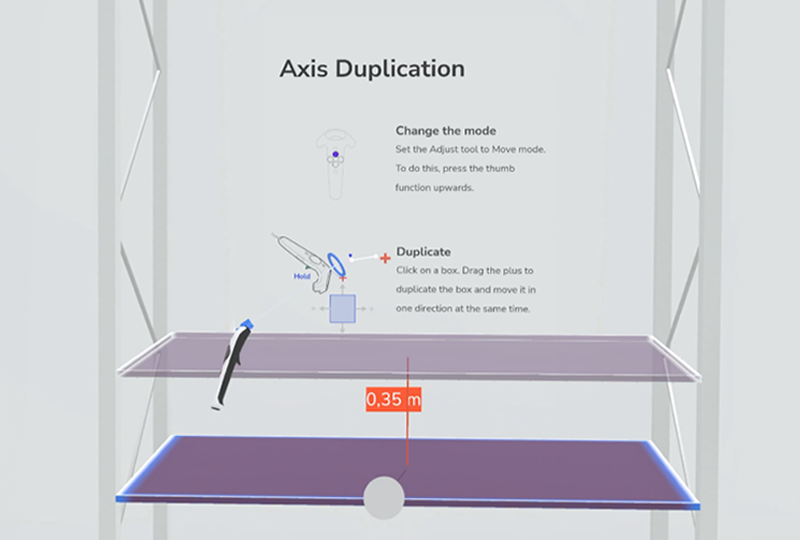

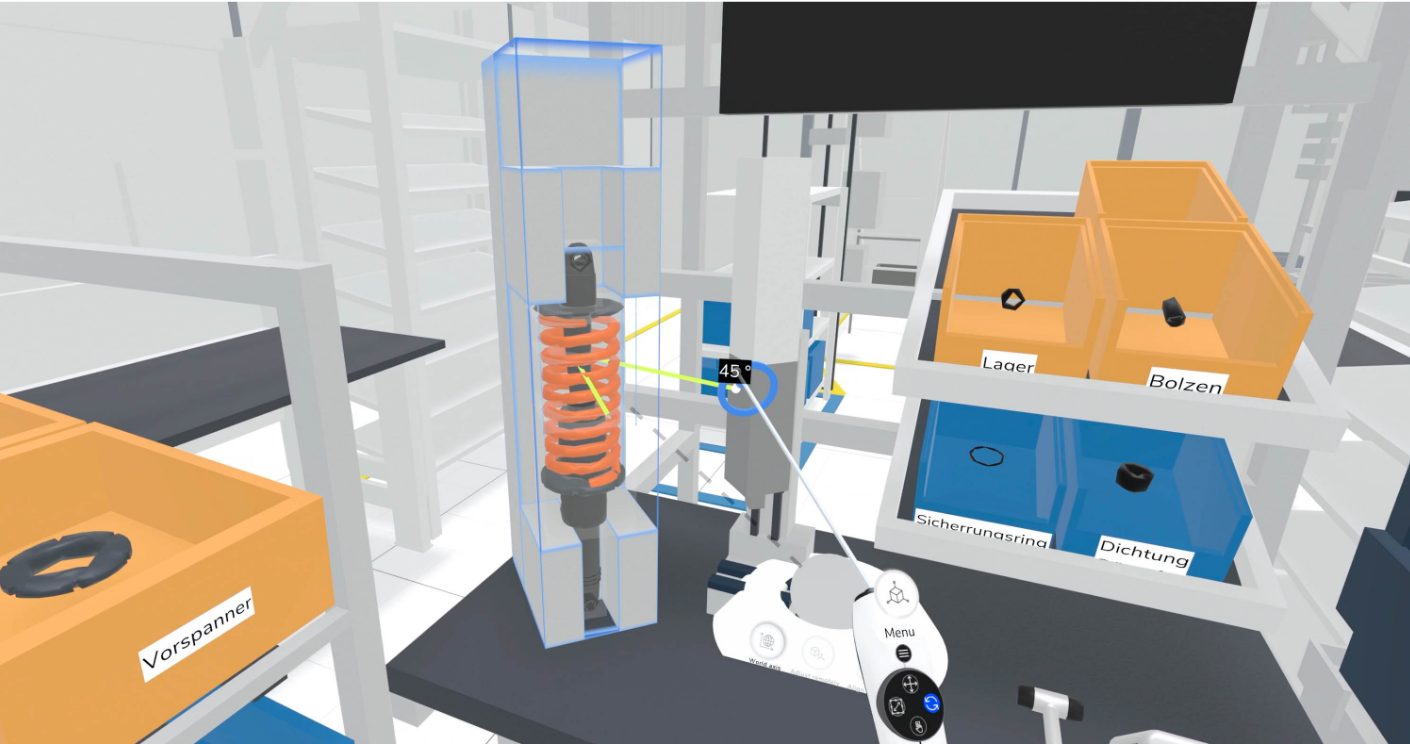

Test your planning

With one click, you can switch from Planning to Testing. The virtual environment then behaves like reality. Run the planned process from start to finish: Real walk-throughs, intuitive grasping, easy assembly. Even during the first test in the virtual space you will realize if the distance between objects is too great or the walking paths are too far. Our customers report: “Only in VR you really become aware of how long three meters of walking distance actually is — otherwise it’s just a number.”

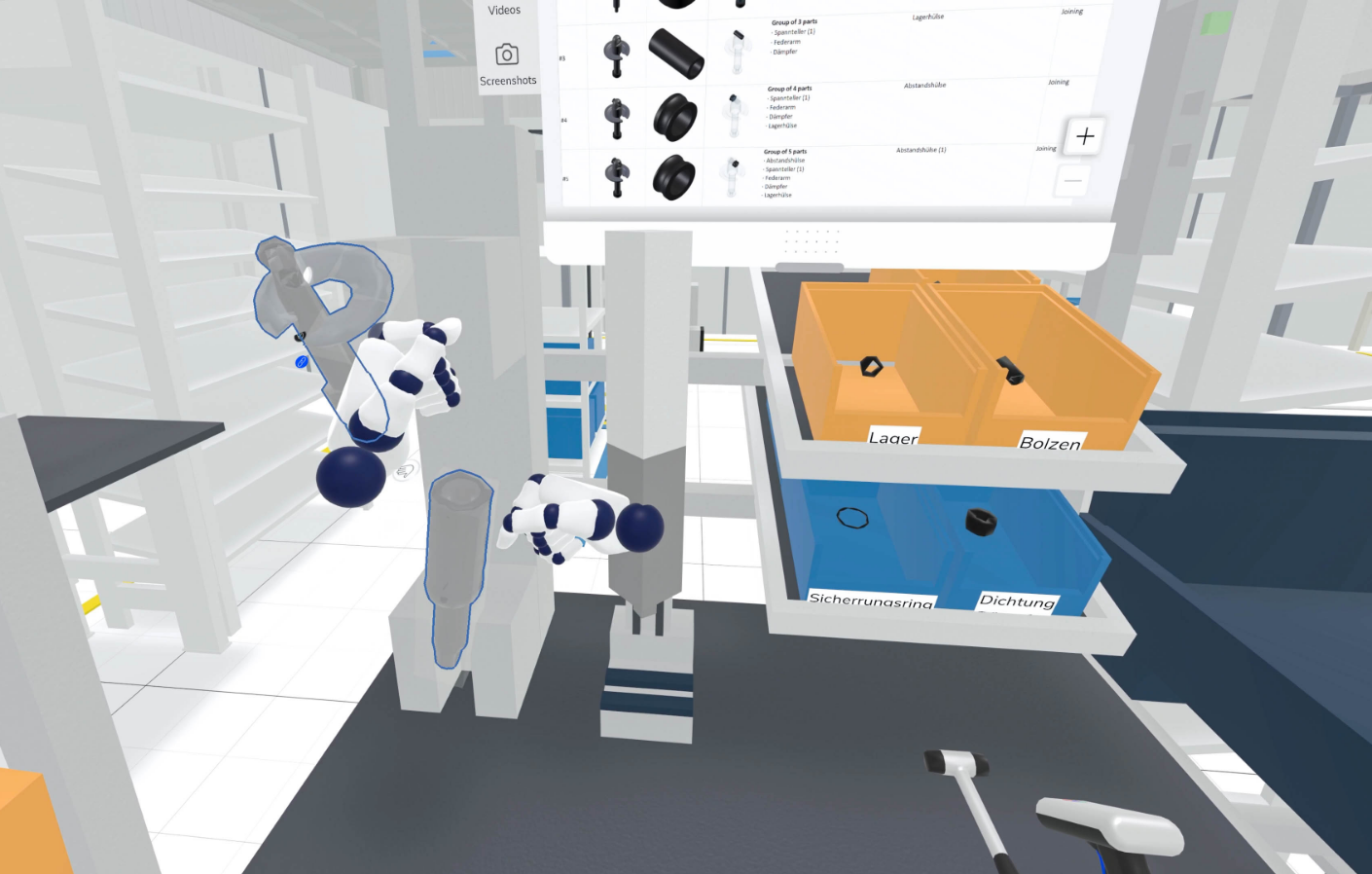

Record your movements

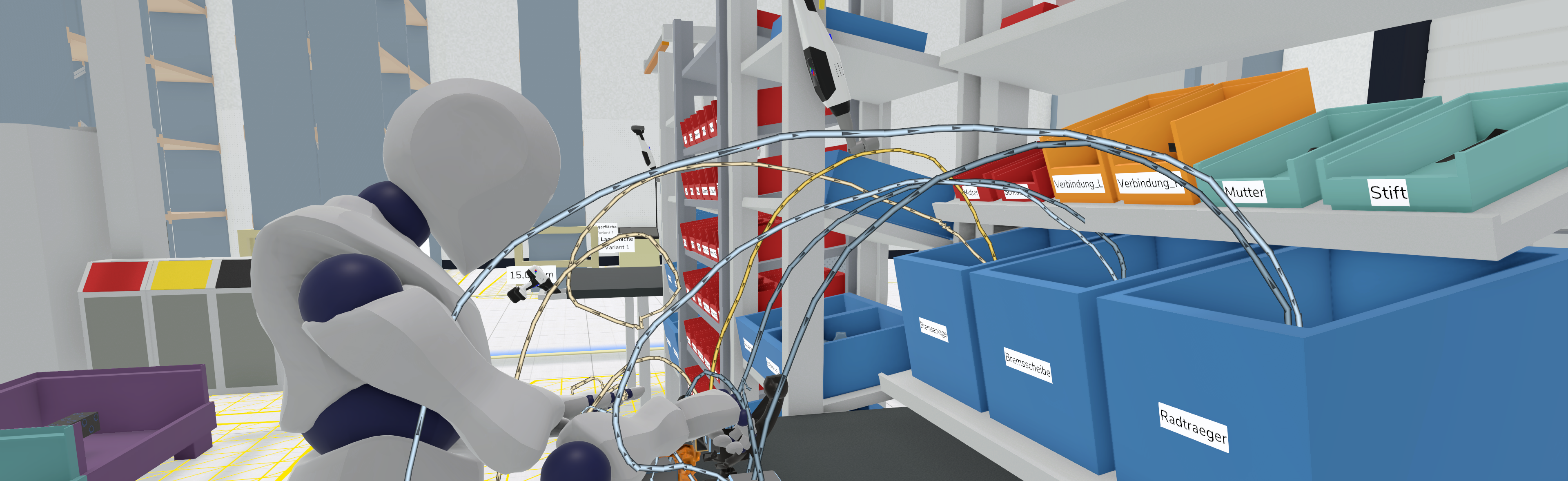

You can record the entire sequence of an assembly process and visualize it with an avatar. Information that is otherwise only available in long tables and complicated expert software is automatically created in Halocline by playing through the assembly process. The information about time, place, distance, weight and assembly method of a component is automatically available for further analysis after testing.

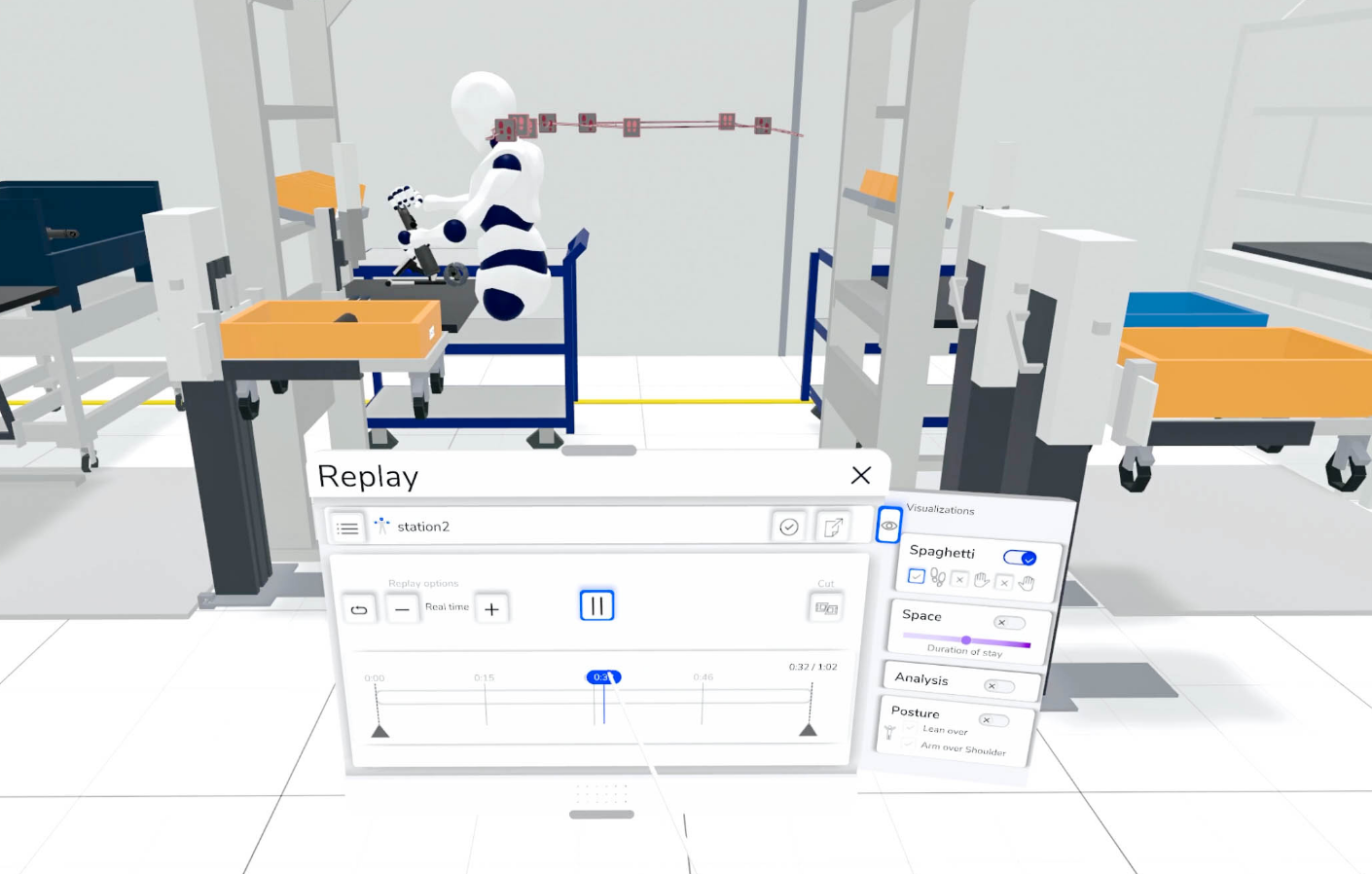

Play and analyze

The recordings can be played back like a video, so the process can be viewed and analyzed in detail. In addition, Halocline offers visualizations of walking & reaching paths, movement spaces & various ergonomics analyses that are automatically generated from the recorded data. This makes it easier to compare and optimize your planning.

Compare and optimize

Gripping and walking paths

Spaghetti diagrams are also used a lot on paper. The advantage in VR, however, is that they are displayed in 3D. This means that every single movement can be traced exactly. These diagrams are created automatically by your movement in VR.

Occupied space

Display the movement area to see where the assemblers are mainly located during the process. The top view provides a good overview to compare variants of a workplace.

Ergonomics

An avatar is created from the movements. This shows where and when the hand was stretched over the shoulder or bent over. In addition, critically placed objects are displayed according to the key indicator method, so that you can check and optimize their position.

Export tables

The motion and object data of the recording can be exported for further use outside of Virtual Reality. With this data you can perform further analysis or use additional simulation software to detail & evaluate the process.

Improve iteratively

Once you have determined the best variant you can optimize it further. With one click you switch back to the planning mode and can adjust the planning there. This way you get the best result with short iteration loops.

Conclusion

VR offers the possibility to implement complicated analyses in a very simple way. This allows you to optimize your planning and make decisions based on a good database. Try it out and see for yourself!